-Measure the angle with a protractor or angle finder.

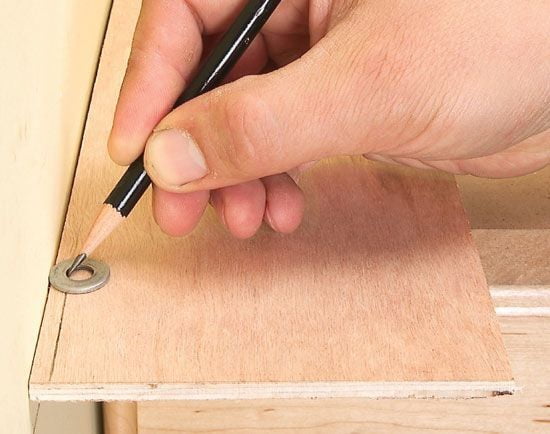

-Mark the angle on the wood with a pencil or knife.

-Cut the angle with a saw.

Best Clamps For Woodworking

There are many different types of clamps for woodworking, each with their own advantages and disadvantages. The type of clamp you need for a particular job depends on the size and shape of the pieces you are clamping, the type of joint you are using, and the materials you are using.

Here are some of the most common types of clamps for woodworking:

C-clamps are the most basic type of clamp. They are named for their shape, which is like the letter C. C-clamps are good for clamping small pieces of wood together, and they can be used with a variety of joints, including butt joints, lap joints, and T-joints.

G-clamps are similar to C-clamps, but they have a wider opening and are better for clamping larger pieces of wood.

F-clamps are also similar to C-clamps, but they have a longer arm and are better for clamping pieces of wood that are further apart.

Pipe clamps are made of two metal pipes that are attached to a clamp head. They are adjustable, so they can be used to clamp a variety of different sizes of wood.

bar clamps are made of a bar with a clamp head on either end. They are adjustable, and can be used to clamp a variety of different sizes of wood.

spring clamps are small clamps that are adjustable and have a spring-loaded clamp head. They are good for clamping small pieces of wood together.

C-clamps, G-clamps, F-clamps, pipe clamps, bar clamps, and spring clamps are all available at most hardware stores.

Woodworking Pro S R O

Woodworking is a great hobby, but it can also be a great profession. There are a lot of different ways to make a living as a woodworker, but the most common ones are by making furniture, cabinets, or other wood products.

The great thing about woodworking is that it can be a very versatile profession. You can make a lot of different things with wood, and there are a lot of different ways to go about it. You can specialize in a certain type of woodworking, or you can be a generalist and make anything from furniture to cabinets to toys.

There are also a lot of different ways to get started in woodworking. You can start your own business, or you can work for someone else. You can work in a factory, or you can work in your own shop. You can also work from home, which can be a great option if you want to start your own business.

No matter what type of woodworking you do, or what type of business you have, there are a few things that are always important. You need to have a good understanding of woodworking techniques, and you need to have a good eye for design. You also need to be able to work with wood safely, and you need to have a good understanding of the materials you’re working with.

If you have these skills, then you can be a successful woodworker. Woodworking is a great profession, and it’s a great way to make a living.

How To Make Woodworking Workbench

There are a few things you need to consider when making a woodworking workbench. The bench should be big enough to accommodate the largest project you plan to work on, but not so big that it takes up too much space in your shop. It should also be sturdy enough to hold up to the pounding it will take from your tools.

The first step is to measure the space you have available and decide on the size of the workbench. Then, using a table saw, miter saw, or circular saw, cut the pieces for the top and legs of the bench. Next, using a drill, countersink the holes for the screws that will hold the top and legs together. Finally, screw the top and legs together and sand the entire bench.

If you are looking for a more sturdy workbench, you can add a shelf or two underneath the top. Just make sure the shelf is the same width as the top and that the screws that hold it in place are countersunk so they don’t protrude.

A woodworking workbench is a necessary piece of equipment for any woodworker. It provides a stable surface to work on and prevents your projects from slipping and sliding around. It can also be customized to fit your specific needs. By following these simple steps, you can build your own woodworking workbench.

Japanese Woodworking Blog

Welcome to the Japanese Woodworking blog, a blog dedicated to the art of Japanese woodworking. In this blog, we will explore the techniques and methods used in Japanese woodworking, and show you how to apply these techniques to your own projects.

In Japanese woodworking, the focus is on creating beautiful and elegant pieces of furniture and woodwork, using simple and elegant techniques. In this blog, we will show you how to create beautiful pieces of furniture and woodwork using these techniques.

We will show you how to create joints using traditional Japanese techniques, such as the mortise and tenon joint and the dovetail joint. We will also show you how to create beautiful finishes using traditional Japanese techniques, such as the shou sugi ban finish.

So, if you are interested in learning about the art of Japanese woodworking, or if you are interested in applying these techniques to your own projects, then this blog is for you. We hope you enjoy it.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.