Woodworking Plans For Benchtop Tool Drawers

There are a few considerations you need to take into account when planning to build a benchtop tool drawer. The first is the size of the drawer. You need to make sure that it will fit the tools you plan to store in it. The second consideration is the construction of the drawer. You need to make sure that it is strong enough to support the weight of the tools. The third consideration is the type of drawer slides you will use. You need to make sure that they are the correct size and type for the drawer you plan to build.

The following plans will show you how to build a benchtop tool drawer that is the correct size and has the correct type of drawer slides. The plans are for a drawer that is 24 inches wide, 18 inches deep, and 3 inches high. The drawer slides are full extension, ball bearing slides.

To build the drawer, you will need the following materials:

– One piece of 3/4 inch plywood, 24 inches wide by 18 inches deep

– One piece of 1/2 inch plywood, 24 inches wide by 18 inches deep

– Two pieces of 3/4 inch by 2 inch by 18 inch lumber

– Two pieces of 3/4 inch by 2 inch by 24 inch lumber

– Four pieces of 3/4 inch by 1 1/2 inch by 18 inch lumber

– Four pieces of 3/4 inch by 1 1/2 inch by 24 inch lumber

– Thirty-two screws, 3 inches long

– Four screws, 1 1/2 inches long

– Six screws, 1 inch long

– One drawer slide, 24 inches long

– One drawer slide, 18 inches long

– One drawer slide, 12 inches long

The first step is to cut the pieces of lumber for the drawer. Cut two pieces of 3/4 inch by 2 inch by 18 inch lumber for the sides of the drawer. Cut two pieces of 3/4 inch by 2 inch by 24 inch lumber for the front and back of the drawer. Cut four pieces of 3/4 inch by 1 1/2 inch by 18 inch lumber for the bottom and top of the drawer.

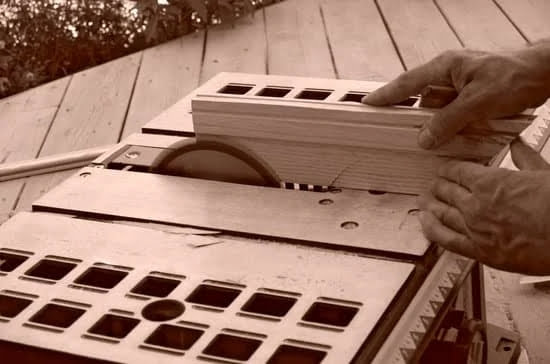

The next step is to drill the pocket holes in the pieces of lumber for the drawer. Drill pocket holes in the two pieces of 3/4 inch by 2 inch by 18 inch lumber for the sides of the drawer. Drill pocket holes in the two pieces of 3/4 inch by 2 inch by 24 inch lumber for the front and back of the drawer. Drill pocket holes in the four pieces of 3/4 inch by 1 1/2 inch by 18 inch lumber for the bottom and top of the drawer.

The next step is to assemble the drawer. Start by attaching the sides of the drawer to the front and back of the drawer with screws. Then attach the bottom of the drawer to the sides of the drawer. Finally, attach the top of the drawer to the sides of the drawer.

The next step is to attach the drawer slides to the drawer. The drawer slides should be attached to the front and back of the drawer. The slides should be attached at the same height on each side.

The last step is to attach the drawer to the benchtop. The drawer should be attached to the benchtop with screws. The screws should be attached at the same height on each side.

Woodworking Tools Exhibition

The woodworking tools exhibition was a great opportunity to see the latest tools and technology in the woodworking industry. There were a lot of great new tools on display, and it was a great opportunity to see how they work and how they can be used to improve your woodworking projects.

The exhibition was a great opportunity to see the latest tools and technology in the woodworking industry. There were a lot of great new tools on display, and it was a great opportunity to see how they work and how they can be used to improve your woodworking projects.

One of the highlights of the exhibition was the new Festool track saw. This saw is designed to make cutting large panels much easier, and it can be easily attached to a track to ensure a straight cut. The saw is also very accurate, and it can be used to make precision cuts in both wood and plastic.

Another highlight of the exhibition was the new DeWalt Flexvolt table saw. This saw is designed for both hobbyists and professional woodworkers, and it features a powerful motor that can handle even the most demanding projects. The saw also features a precision fence system that ensures accurate cuts every time.

The exhibition was also a great opportunity to see the latest tools and technology from other leading brands, such as Bosch, Makita, and Ridgid. These brands all offer a wide range of tools that can be used to improve your woodworking projects, and they all come with a range of features that can make your work easier and more efficient.

If you’re interested in woodworking, then the woodworking tools exhibition is definitely worth a visit. It’s a great opportunity to see the latest tools and technology in the industry, and it’s also a great opportunity to learn more about how these tools can be used to improve your woodworking projects.

Woodworking Hand Tool Wall Cabinet

This cabinet was designed to store hand tools on a wall in my shop. It is made from 3/4″ plywood with a simple butt joint construction. The cabinet has a hinged door that opens to reveal 6 shelves that can hold a variety of hand tools.

The cabinet is designed to be mounted to a wall with 2 screws. The screws are hidden behind the door when it is closed. The cabinet can also be mounted to a stud in the wall for added strength.

The cabinet is finished with a coat of primer and a coat of paint. The paint color is matched to the trim in my shop.

This cabinet is a great way to store hand tools in a small space. It is easy to build and can be made from scraps of plywood.

Woodworking Tools Arlington Texas

There are many different types of woodworking tools Arlington Texas, each with its own specific purpose. Some are used for cutting, others for shaping, and still others for joining pieces of wood together.

The most basic of all woodworking tools is the saw. There are many different types of saws, including the hand saw, the power saw, and the jigsaw. The hand saw is the oldest type of saw, and is still used for many smaller projects. The power saw is used for larger projects, and the jigsaw is used for shaping curved pieces of wood.

Another common woodworking tool is the drill. There are many different types of drills, including the hand drill, the power drill, and the cordless drill. The hand drill is used for smaller projects, the power drill is used for larger projects, and the cordless drill is used for projects that require more mobility.

The hammer is another common woodworking tool. There are many different types of hammers, including the claw hammer, the ball-peen hammer, and the mallet. The claw hammer is used for driving nails, the ball-peen hammer is used for shaping metal, and the mallet is used for pounding chisels.

Other common woodworking tools include the screwdriver, the drill bit, and the chisel. The screwdriver is used for driving screws, the drill bit is used for drilling holes, and the chisel is used for cutting and shaping wood.

Woodworking tools Arlington Texas can be used for a variety of different projects, from simple repairs to complex furniture pieces. By learning about the different types of woodworking tools and their purposes, you can select the right tools for the job and complete your projects with ease.

Saw Woodworking Hand Tools List

A saw is a tool that is used to cut different materials. There are many different types of saws that are used for different purposes.

The most common type of saw is the hand saw. A hand saw is a saw that is held in the hand and is used to cut materials such as wood. A hand saw has a blade that is attached to a handle. The blade is used to cut the material that is being worked on.

There are many different types of hand saws. The most common type of hand saw is the crosscut saw. A crosscut saw is a saw that is used to cut wood perpendicular to the grain. The blade of a crosscut saw is designed to cut quickly and smoothly through the wood.

Another common type of hand saw is the rip saw. A rip saw is a saw that is used to cut wood parallel to the grain. The blade of a rip saw is designed to cut quickly and smoothly through the wood.

There are also many specialty hand saws that are used for specific purposes. Some examples of specialty hand saws include the coping saw, the fret saw, and the tenon saw.

A saw is a very useful tool that can be used to cut a variety of materials. There are many different types of saws that are available, each with its own unique set of benefits. When selecting a saw, it is important to consider the type of material that will be cut, the type of cut that is desired, and the overall size and weight of the saw.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.