Woodworking is a craft that requires not only skill, but also the right tools. While there are plenty of high-quality woodworking tools available for purchase, there is a unique satisfaction that comes from building your own. In this article, we will delve into the world of DIY woodworking tools, exploring the benefits and possibilities that come with crafting your own instruments.

Building your own woodworking tools provides a sense of ownership and accomplishment. Not only do you have control over every detail, but you also gain a deeper understanding of how these tools work and can customize them to fit your specific needs. Additionally, building your own tools can be more cost-effective in the long run, as many materials can be repurposed or found at a lower cost than purchasing pre-made tools.

In this guide, we will cover everything you need to know about creating your own woodworking tools. We will start by discussing key tools that are ideal for building yourself, such as saws and chisels. Then, we will explore the best materials for construction and provide safety tips to ensure a secure process.

You will also find a step-by-step guide to help you build your very first tool from scratch, followed by tips on customizing and maintaining your creations. Finally, we will showcase inspiring stories of woodworkers who have successfully built their own tools.

If you’re ready to take your woodworking skills to the next level and experience the pride that comes with crafting your own instruments, join us on this journey as we guide you through the world of building your own woodworking tools.

Understanding the Basics

Building your own woodworking tools can be a rewarding and fulfilling experience. Not only does it enable you to save money, but it also allows you to customize your tools to suit your specific needs. In this section, we will explore the basics of key tools that you can build yourself.

The Workbench

The workbench is the centerpiece of any woodworking shop and building one from scratch can be a great starting point for your DIY journey. A sturdy workbench provides a stable surface for all your projects and ensures accuracy during cutting, drilling, and sanding.

When building your own workbench, consider factors such as the size, height, and material. It’s important to choose durable materials like hardwood for the top surface that can withstand heavy loads and resist warping or shrinking over time.

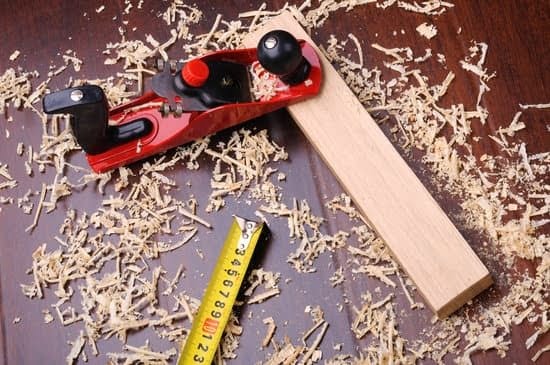

Hand Planes

Hand planes are essential tools in woodworking that allow you to shape and finish wood surfaces with precision. Building your own hand plane gives you the opportunity to create a tool that perfectly suits your preferences and working style. You will need some basic woodworking skills and access to woodworking tools like a bandsaw, jointer, planer, and table saw. Consider using quality materials like hardwood or brass for the body of the plane and high-carbon steel for the blade.

Sanding Blocks

Sanding is an integral part of woodworking that helps achieve smooth finishes on wooden surfaces. Instead of buying sanding blocks from the store, you can easily make them yourself at home. All you need is a piece of scrap wood cut into a comfortable shape that fits well in your hand. Attach sandpaper using adhesive or use hook-and-loop fasteners for easy removal and replacement of sandpaper sheets.

By understanding how to build these basic woodworking tools yourself, you can save money while also gaining valuable knowledge about their construction and functionality. The process of building your own tools not only provides a sense of accomplishment but also allows you to tailor them to your specific woodworking needs and preferences. So, roll up your sleeves and start building.

Selecting the Right Materials

When it comes to building your own woodworking tools, selecting the right materials is crucial for ensuring durability, functionality, and safety. By choosing high-quality materials, you can create tools that will not only last for a long time but also provide optimal performance. Here are some key considerations when selecting materials for DIY woodworking tool construction.

Choosing the Right Wood

The type of wood used in building your woodworking tools can greatly impact their strength and performance. Hardwoods such as oak, maple, and walnut are commonly recommended for tool handles due to their durability and resistance to wear and tear. These woods also have a pleasant feel in hand, making them comfortable to use for extended periods. However, softer woods like pine or ash may be suitable for less demanding tools or parts that require more flexibility.

Utilizing Metal Components

While wood is the predominant material used in tool construction, incorporating metal components can enhance both functionality and strength. For example, using steel for blades or cutting edges can ensure sharpness and longevity. Stainless steel or other corrosion-resistant metals are ideal choices for parts that may come into contact with moisture or require frequent cleaning.

Exploring Alternative Materials

In addition to traditional wood and metal, there is an array of alternative materials that can be considered for certain woodworking tool applications. For instance, carbon fiber can provide excellent strength-to-weight ratio and resilience against bending or breaking. Composite materials like fiberglass-reinforced plastic could offer versatility while maintaining sufficient strength. Depending on the specific function of the tool you’re building, it’s worth exploring these options to find the best material choice.

By carefully selecting the right materials for your DIY woodworking tools, you can ensure that they not only look great but also perform optimally. Whether it’s choosing hardwoods for handles or incorporating metal components where needed, thoughtful selection of materials will contribute to the overall quality of your handcrafted tools.

Essential Safety Tips

Building your own woodworking tools can be a rewarding and fulfilling experience, but it is important to prioritize safety throughout the process. This section will provide essential safety tips to help you maximize safety while building your own woodworking tools.

- Wear Protective Gear: Safety should always come first when working with tools. Make sure to wear appropriate protective gear such as safety goggles, gloves, and ear protection to protect yourself from potential injuries.

- Use Proper Ventilation: Many woodworking projects involve the use of chemicals or paint. It is important to work in a well-ventilated area or use proper ventilation systems to avoid inhaling harmful fumes.

- Follow Tool Manuals: When building your own woodworking tools, it is crucial to carefully read and understand the manuals for each tool you are using. This will help you operate them correctly and safely.

- Maintain a Clean Workspace: A cluttered workspace can increase the risk of accidents and injuries. Keep your work area clean and organized at all times, ensuring that there are no obstructions or tripping hazards.

- Take Precautions with Power Tools: Power tools can be dangerous if not used properly. Before operating any power tools, make sure they are in good condition, properly grounded, and that you have received proper training on their safe usage.

- Keep First Aid Kit Handy: Accidents can happen even with the utmost precautionary measures. Always have a first aid kit readily available in case of minor cuts, bruises, or other injuries.

- Seek Assistance When Needed: If you are new to woodworking or unsure about any aspect of building your own tools, don’t hesitate to seek guidance from experienced woodworkers or attend workshops where experts can provide assistance.

Remember, prioritizing safety throughout the process of building your own woodworking tools is crucial for minimizing the risk of accidents and injuries. By following these essential safety tips, you can ensure a safe and enjoyable experience while crafting your own tools.

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Protective goggles, gloves, and ear protection should be worn to prevent injuries. |

| Use Proper Ventilation | Work in a well-ventilated area or use ventilation systems when working with chemicals or paint. |

| Follow Tool Manuals | Carefully read and understand the manuals for each tool to operate them safely. |

| Maintain a Clean Workspace | Keep your work area clean and organized to reduce the risk of accidents. |

| Take Precautions with Power Tools | Ensure power tools are in good condition, properly grounded, and receive proper training on safe usage. |

Step-by-Step Guide

Building your own woodworking tools can be a rewarding and fulfilling endeavor. Not only do you get the satisfaction of creating something with your own hands, but you also have the opportunity to customize the tool to fit your specific needs. In this step-by-step guide, we will walk you through the process of building your first woodworking tool from scratch.

- Choose a Woodworking Tool: The first step is to decide which tool you want to build. Whether it’s a hand plane, a chisel, or a mallet, pick a project that aligns with your interests and skill level.

- Gather Your Materials: Once you have chosen a tool to build, gather all the necessary materials. This may include wood for the handle, metal for the blade or head, and any hardware needed for assembly.

- Design and Plan: Before you start cutting and shaping the materials, take some time to design and plan out your tool. Consider the dimensions, ergonomics, and functionality of the tool. Sketch out your design or create a detailed plan on paper.

- Prepare Your Wood: If you are building a tool with a wooden handle, begin by preparing the wood. Cut it to size and shape using a saw or other cutting tools. Sand down any rough edges or imperfections.

- Shape and Form Metal Components: For tools that require metal components such as blades or heads, use appropriate tools like grinders or files to shape and form them according to your design.

- Assemble Your Tool: Once all components are prepared, follow your design plan to assemble the tool. Use screws, glue or other fasteners as necessary.

- Fine-tune and Test: After assembling the tool, fine-tune any rough areas or edges with sandpaper or other finishing tools. Test the functionality of your creation to ensure it works as intended.

- Personalize Your Tool: Lastly, add any personal touches or customization to make the tool truly your own. This could include carving designs into the handle, adding decorative elements or engraving your initials.

By following this step-by-step guide, you will be able to build your first woodworking tool from scratch. Remember to take your time and pay attention to detail throughout the process. Enjoy the journey of creating something unique that will serve you well in your woodworking projects.

Enhancing Efficiency and Functionality

Customizing your DIY woodworking tools not only enhances their efficiency and functionality but also allows you to tailor them to fit your specific needs and preferences. By making small adjustments or adding unique features, you can greatly improve the performance of your tools and make them more comfortable and enjoyable to use. Here are some tips and ideas for customizing your DIY woodworking tools:

- Ergonomic Modifications: One way to enhance the functionality of your tools is by making ergonomic modifications. This involves adjusting the shape, size, or grip of the tool to provide better comfort and reduce strain on your hands and body during use. For example, you can add foam or rubber grips to handle surfaces for a more secure and less fatiguing hold.

- Personalized Accessories: Another way to customize your woodworking tools is by adding personalized accessories that improve their functionality. You can create jigs, guides, or attachments that help with specific tasks or enhance accuracy and precision. For instance, a customized miter sled for a table saw can provide better control when making angled cuts.

- Upgraded Components: Consider upgrading certain components of your tools to increase their efficiency. For example, replacing standard blades with high-quality ones that are specifically designed for different types of wood can significantly improve cutting performance. Likewise, upgrading motor power or adding speed controls can help optimize the performance of power tools such as routers or drills.

To ensure successful customization, it’s important to have a clear understanding of the tool’s function and how different modifications may affect its performance. Additionally, always prioritize safety when customizing your DIY woodworking tools by following manufacturer guidelines and using appropriate materials and techniques.

By customizing your own woodworking tools, you not only create unique pieces that reflect your personal style but also gain a deeper understanding of how each tool functions. Experimentation with customization allows you to develop a greater mastery over your craft while enhancing efficiency in your woodworking projects.

Maintenance and Care

Proper maintenance and care are crucial in preserving and extending the lifespan of your handcrafted woodworking tools. By taking the time to care for your tools, you can ensure that they remain in optimal condition for many years of use. Here are some essential tips for properly maintaining and caring for your handcrafted tools.

Firstly, it is important to keep your tools clean and free from debris. After each use, take the time to wipe down your tools with a clean cloth to remove any sawdust, dirt, or other materials that may have accumulated. This will help prevent the build-up of grime and reduce the risk of rusting or corrosion.

Additionally, regularly sharpening your handcrafted tools is key to maintaining their effectiveness. Dull blades not only hinder performance but can also be dangerous to work with. Invest in a high-quality sharpening system and learn how to properly sharpen each type of tool in your collection.

Another important aspect of tool maintenance is proper storage. After use, make sure to store your handcrafted tools in a dry and clean environment. Consider investing in a toolbox or wall-mounted storage system to keep your tools organized and protected from damage.

Lastly, routine inspections are essential for identifying any potential issues with your handcrafted tools. Regularly examine each tool for signs of wear or damage such as loose handles, chipped edges, or bent parts. If any issues are found, address them promptly by repairing or replacing the affected components.

By following these maintenance and care tips, you can ensure that your handcrafted woodworking tools remain in top condition. Proper preservation will not only extend their lifespan but also contribute to the quality of your woodworking projects. Treat your handmade tools with care and they will serve you well for years to come.

Exploring Advanced Techniques

Woodworking is a craft that offers endless possibilities and opportunities for creativity. For those who have mastered the basics of building their own woodworking tools, it may be time to explore more advanced techniques and push the boundaries of what can be achieved. This section will delve into the world of complex DIY woodworking tools and provide insights and inspiration for those looking to take their craftsmanship to the next level.

One of the most exciting aspects of advanced woodworking tool construction is the ability to create specialized tools that are tailored to specific tasks. From intricate joinery work to unique shaping and carving techniques, these complex DIY tools allow woodworkers to achieve results that would be difficult or even impossible with commercially available options. The possibilities are truly limitless, limited only by the woodworker’s skill and imagination.

When it comes to advanced DIY woodworking tools, precision and accuracy are paramount. These tools require meticulous planning, careful measurements, and precise execution in order to function optimally. Woodworkers looking to venture into this realm should invest in high-quality materials, such as durable metals or exotic hardwoods, that can withstand rigorous use without compromising performance.

| Advanced Technique | Description |

|---|---|

| Inlaying | This technique involves inserting small pieces of contrasting material into channels cut into the surface of a workpiece. |

| Bow Saws | A specialized saw used for intricate cutting tasks such as curved lines or delicate contours. |

| Router Jigs | Jigs used with a router for creating complex joinery including dovetails, box joints, or mortise-and-tenon joints. |

As with any woodworking project, safety should always be a top priority when working with complex DIY tools. Advanced techniques often involve more intricate movements and handling of materials, which can increase the risk of accidents. Woodworkers should adhere to proper safety practices, including wearing personal protective equipment such as goggles, gloves, and ear protection. It is also important to have a well-ventilated workspace and to maintain sharp cutting edges on all tools to prevent any mishaps.

Spotlight on Successful DIYers

One of the most inspiring aspects of woodworking is the creativity and ingenuity that comes with building your own tools. In this section, we will shine a spotlight on some successful DIYers who have taken the plunge and crafted their own woodworking tools. These stories not only demonstrate what can be accomplished with determination and resourcefulness, but also serve as a source of inspiration for those looking to embark on their own tool-building journey.

One such DIYer is John Petersen from Portland, Oregon. Faced with limited funds and a passion for woodworking, Petersen decided to build his own table saw from scratch. He meticulously researched various designs, studied engineering principles, and sought advice from experienced woodworkers in online forums. Armed with this knowledge, he set out to gather the necessary materials and slowly began constructing his custom-built table saw.

After months of dedicated work, Petersen completed his homemade table saw – a true labor of love. Not only did he save money by building it himself, but he also gained an intimate understanding of its inner workings and was able to fine-tune it to meet his specific needs. Today, Petersen’s table saw stands proudly in his workshop and serves as a testament to his skill and determination.

Another remarkable story comes from Barbara Thompson, a retired teacher turned DIY woodworker. Thompson had always been fascinated by hand planes but found them too expensive to purchase. Undeterred by this obstacle, she decided to build her own wooden hand plane using traditional techniques passed down through generations. With guidance from experienced woodworkers and hours of practice carving wood blocks into shape, Thompson finally achieved her goal.

Thompson’s homemade wooden hand plane has become an essential tool in her woodworking endeavors. Not only does it perform impeccably well at smoothing rough surfaces, but its personalized design makes it all the more special for Thompson. She often receives compliments on her one-of-a-kind hand plane and takes great pride in the fact that she crafted it with her own two hands.

These stories of successful DIYers remind us that building our own woodworking tools is not only a way to save money, but also an opportunity to unleash our creativity and problem-solving skills. By taking on the challenge of tool-building, we can experience the satisfaction of using tools that are uniquely tailored to our needs and preferences. So, let these inspiring stories fuel your motivation as you embark on your own journey of crafting your own woodworking tools.

Final Thoughts

Crafting your own woodworking tools is not just a practical skill, but also an inspiring and fulfilling journey. Throughout this article, we have explored the benefits and possibilities of building your own tools, understanding the basics, selecting the right materials, and prioritizing safety.

We have provided a step-by-step guide for building your first tool from scratch, as well as tips for enhancing efficiency and functionality. We have emphasized the importance of maintenance and care to preserve and extend the lifespan of your handcrafted tools.

Building your own woodworking tools is not just about saving money or having custom-made equipment. It is about embracing a craft that allows you to connect with the material and create something truly unique. By investing time and effort into crafting your own tools, you develop a deeper understanding of their inner workings and gain a greater appreciation for both traditional craftsmanship and innovation.

Furthermore, by exploring advanced techniques in DIY woodworking tool construction, you can push the boundaries of what is possible and create tools that are tailored to your specific needs and preferences. Whether it’s designing intricate jigs or inventing new types of hand planes, there is no limit to what you can achieve when you embrace this journey.

Finally, we cannot overlook the inspiring stories of successful DIY woodworkers who have built their own tools. Their stories serve as a reminder that with dedication, perseverance, and creativity, anyone can embark on this journey. Through trial and error, they have honed their skills over time to become true masters of their craft.

In conclusion, building your own woodworking tools is more than just a practical choice; it is an art form that allows you to express yourself while creating functional works of art. So why not start embracing this journey today? Discover the joy of crafting your own tools while expanding your knowledge and skills in woodworking.

Unlock endless possibilities as you explore new techniques and techniques alongside like-minded individuals who share your passion for woodworking. Build something extraordinary with your very own hands and leave a lasting legacy in the world of craftsmanship. The journey awaits you.

Frequently Asked Questions

What is the essential tool for every woodworker?

The essential tool for every woodworker is a good quality set of woodworking hand tools. These include items such as a chisel, mallet, handsaw, plane, and measuring tools like a tape measure or combination square.

These basic hand tools are versatile and can be used for a wide range of woodworking tasks such as cutting, shaping, smoothing, and measuring wood. While power tools can also be useful in certain situations, having a solid foundation with hand tools is crucial for any woodworker.

How to get free woodworking tools?

One way to get free woodworking tools is by joining local woodworking or community groups. Often, fellow woodworkers are willing to lend or donate unused or unwanted tools to others who share their passion.

Online forums and social media groups dedicated to woodworking are great places to connect with other enthusiasts who may be giving away free tools or looking to sell at affordable prices. Additionally, some organizations or individuals organize tool drives or exchange programs where people can donate or swap their unused tools.

What do I need to start woodworking at home?

To start woodworking at home, there are a few essential things you will need. First and foremost is a dedicated workspace: it could be a garage, workshop, or even just a corner in your basement or backyard shed. Having sufficient space for both working on your projects and storing your tools is important. Next, you’ll need some basic hand tools like saws, chisels, planes, hammers, screwdrivers, and clamps.

As you gain more experience and tackle different projects, you may also want to invest in power tools such as a drill press or table saw. Safety equipment like safety goggles, hearing protection, and dust masks should never be overlooked when working with wood. Lastly, having access to good instructional resources such as books or online tutorials will help you learn new techniques and refine your skills over time.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.