Are you wondering where to buy quality hand woodworking tools NYC? Woodworking is a beloved craft that has been around for centuries, and it requires the right tools to create beautiful and functional pieces.

Whether you are a beginner or an experienced woodworker, having access to high-quality hand woodworking tools is essential for any project. In this article, we will explore the importance of quality hand woodworking tools, provide recommendations for the top 5 stores in NYC, offer tips for choosing the right tools, and share expert advice on maintenance and care.

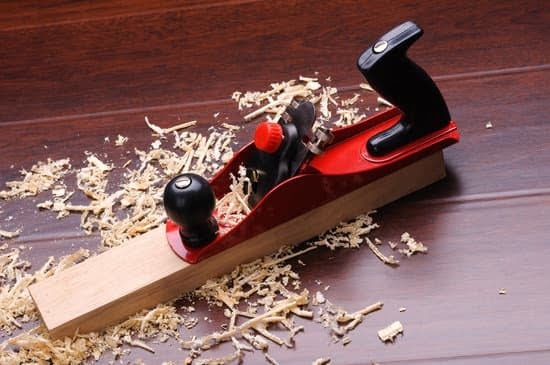

Woodworking is not only a hobby but also a skill that requires precision, attention to detail, and the right set of tools. Quality hand woodworking tools are essential for achieving professional results and making the woodworking process more enjoyable. From chisels to hand saws to planes, having access to reliable and durable tools can make all the difference in your woodworking projects.

If you’re in New York City and looking to invest in quality hand woodworking tools, it’s important to know where to find them. With numerous stores specializing in woodworking supplies, it can be overwhelming to choose the best one.

That’s why we’ve compiled a list of the top 5 recommended stores in NYC where you can purchase top-notch hand woodworking tools. Whether you’re looking for specialty items or general supplies, these stores have everything you need to kickstart your next project with confidence.

Understanding the Importance of Quality Hand Woodworking Tools

Enhanced Precision and Accuracy

Quality hand woodworking tools are designed to provide enhanced precision and accuracy, which are essential for crafting high-quality woodwork. Whether you are working on intricate details or large-scale projects, having tools that can deliver precise cuts, measurements, and finishes is crucial. Investing in high-quality tools ensures that you can achieve professional-level results with your woodworking projects.

Durability and Longevity

One of the key factors in understanding the importance of quality hand woodworking tools is their durability and longevity. When you purchase tools from reputable brands known for their craftsmanship, you can expect them to withstand the test of time.

High-quality woodworking tools are made from robust materials and undergo rigorous testing to ensure that they can endure the demands of regular use. This not only saves you money in the long run by avoiding frequent replacements but also gives you peace of mind knowing that your tools will consistently perform at their best.

Safety and Comfort

Quality hand woodworking tools also prioritize safety and comfort for the user. Ergonomically designed handles, advanced safety features, and superior blade sharpness are some aspects that distinguish premium quality tools from lower-grade counterparts. By using high-quality tools, woodworkers can minimize the risk of accidents or injuries during their projects while also enjoying a comfortable and controlled grip.

By understanding these key reasons why quality hand woodworking tools matter, woodworkers in NYC can make informed decisions on where to buy quality hand woodworking tools NYC to enhance their craft and achieve outstanding results in their projects.

Top 5 Recommended Stores for Quality Hand Woodworking Tools in NYC

Are you an aspiring woodworker or a seasoned professional looking for the best quality hand woodworking tools in NYC? Look no further. Here are the top 5 recommended stores where you can find a wide selection of high-quality woodworking tools to suit your needs:

1. Woodcraft – This renowned store offers a diverse range of hand woodworking tools, from chisels and hand saws to clamps and carving tools. With knowledgeable staff and a commitment to quality, Woodcraft is a go-to destination for woodworking enthusiasts in NYC.

2. Tools for Working Wood – Specializing in traditional hand tools, Tools for Working Wood is a treasure trove for those who appreciate fine craftsmanship. Explore their collection of heirloom-quality hand planes, marking knives, and measuring tools.

3. Gramercy Tools – For premium quality hand woodworking tools crafted with precision, Gramercy Tools is the place to go. Their line of specialized hand saws, rasps, and spokeshaves are meticulously designed to meet the needs of discerning woodworkers.

4. Brooklyn Tool & Craft – This Brooklyn-based store offers an impressive selection of handcrafted woodworking tools sourced from local artisans and renowned manufacturers alike. From hand planes to carving sets, you’ll find everything you need to elevate your woodworking projects.

5. TFWW Store – The Toolworks Store offers an extensive range of high-quality hand woodworking tools from reputable brands such as Lie-Nielsen Toolworks and Veritas. Whether you’re in need of specialty layout tools or precision cutting instruments, TFWW has got you covered.

Now that you know where to buy quality hand woodworking tools NYC, you can embark on your next woodworking project with confidence knowing that you have access to the best tools available. Happy woodworking.

Tips for Choosing the Right Hand Woodworking Tools for Your Projects

When it comes to woodworking, having the right tools is essential for the success of your projects. With so many options available, it can be overwhelming to choose the right hand woodworking tools for your specific needs. Here are a few tips to help you make the best decision when selecting your tools.

Consider the Type of Woodworking Projects You’ll Be Working On

Before purchasing hand woodworking tools, it’s important to consider the type of projects you’ll be working on. If you’re focusing on intricate woodcarving, then a set of quality carving chisels would be essential. For larger furniture-making projects, investing in high-quality hand saws and planes would be more practical. Understanding your specific needs will help you narrow down the types of tools required for your projects.

Quality Over Quantity

When it comes to hand woodworking tools, quality should always take precedence over quantity. It’s better to invest in a few high-quality tools that will last a lifetime than to purchase an assortment of low-quality ones that will need frequent replacing. Look for reputable brands known for their craftsmanship and durability, as they are more likely to provide reliable tools that will stand the test of time.

Ergonomics and Comfort

Comfort and ergonomics are often overlooked when choosing hand woodworking tools, but they play a crucial role in ensuring your safety and productivity. Look for tools with comfortable handles that allow for a secure grip and reduce strain on your hands during prolonged use. Testing out different options in person can give you a better sense of which tools feel most comfortable for you.

By keeping these tips in mind, you can make informed decisions when purchasing hand woodworking tools

Expert Advice

Proper maintenance and care of hand woodworking tools are crucial to ensuring their longevity and optimal performance. Whether you are a beginner or an experienced woodworker, taking care of your tools is essential in preserving their quality. Here are some expert tips on how to maintain and care for your hand woodworking tools:

1. Clean your tools regularly: After each use, it is important to clean off any sawdust, dirt, or debris from your hand woodworking tools. Use a brush or a cloth to remove any build-up that could potentially damage the tool over time.

2. Store your tools properly: When not in use, it is important to store your hand woodworking tools in a dry and cool environment to prevent rusting. Consider investing in a tool chest or wall-mounted tool rack to keep your tools organized and protected.

3. Sharpen blades and edges: Keeping the blades and edges of your hand woodworking tools sharp is essential for achieving precise cuts and smooth finishes. Invest in a quality sharpening stone or file, and regularly sharpen the blades of your chisels, planes, and saws.

By following these expert tips on maintaining and caring for your hand woodworking tools, you can ensure that they will continue to serve you well for years to come.

Remember that finding quality hand woodworking tools NYC offers can significantly impact the longevity of these products’ service life as well.

Building Your Woodworking Tool Collection

Whether you’re just starting out in the craft of woodworking or have been honing your skills for years, having the right tools is essential for creating quality pieces. Building a collection of woodworking tools can seem daunting, especially with so many options available. However, there are a few must-have tools that every woodworker should consider adding to their collection.

For beginners, some essential hand woodworking tools to start with include a quality set of chisels, a handsaw, and a block plane. These basic tools will allow you to tackle a wide variety of projects and get a feel for working with wood. As you progress and take on more advanced projects, consider adding specialty planes such as a shoulder plane or router plane to refine joints and create smooth surfaces.

For experienced woodworkers looking to expand their tool collection, investing in high-quality hand planes is key. A good smoothing plane, jack plane, and jointer plane are indispensable for achieving precise and smooth finishes on your workpieces. Additionally, consider adding specialty saws like dovetail saws and tenon saws to tackle complex joinery tasks with ease.

When considering where to buy quality hand woodworking tools in NYC, it’s important to visit reputable stores known for their selection and expertise in woodworking tools. With the right variety of top-notch tools at your disposal, you’ll be well-equipped to take on any woodworking project that comes your way.

Conclusion

In conclusion, the art of woodworking is a fulfilling and timeless craft that has captured the hearts of many artisans in New York City. As we have discovered throughout this article, the quality of hand woodworking tools plays a crucial role in the success and satisfaction of woodworking projects. Fortunately, NYC offers an array of top-notch stores that cater to the needs of woodworkers, providing them with high-quality tools to bring their creations to life.

When it comes to finding the best quality hand woodworking tools in NYC, woodworkers can explore renowned stores such as Tools for Working Wood, The Home Depot, Lee Valley Tools, Brooklyn Tool and Craft, and Gramercy Tools. These establishments are known for their impressive selection of hand tools that meet the standards of even the most discerning woodworkers. With these options readily available, local artisans can easily access premium tools that will enhance their craft.

Aspiring woodworkers may feel overwhelmed when it comes to choosing the right hand woodworking tools for their projects. However, with expert advice and guidance on proper maintenance and care techniques for these tools, they can make informed decisions that will ultimately optimize their woodworking experience.

By building a comprehensive tool collection consisting of must-have items for both beginners and experts, woodworkers can equip themselves with everything they need to delve deeper into this ancient yet ever-evolving craft. So take advantage of what NYC has to offer and find your perfect hand woodworking tools today.

Frequently Asked Questions

Who Makes the Best Woodworking Tools?

The best woodworking tools are often subjective and depend on the specific needs of the woodworker. However, brands like Bosch, DeWalt, and Festool are often considered among the top manufacturers due to their quality, durability, and range of products.

Are Any Woodworking Tools Made in USA?

Yes, there are woodworking tools made in the USA. Brands such as Stanley, Milwaukee Tool, and Delta Machinery produce a variety of woodworking tools domestically. These companies have a long history of producing high-quality tools for craftsmen and hobbyists alike.

What Is the Tool Most Used in Your Woodworking Shop?

In my woodworking shop, the tool that sees the most use is definitely the table saw. It’s an essential tool for making precise cuts on wood pieces of all sizes and shapes. The versatility and accuracy of a good table saw make it indispensable in any woodworking project.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.