Introduction

Figuring angles in woodworking is a key skill for the aspiring woodworker. It isn’t easy, but having the ability to accurately cut and shape wood at precise angles can be very beneficial when it comes to completing a project. Not only does figuring angles allow for more efficient use of material, reducing waste and cost, but it also increases safety by ensuring that joints are strong and square. Knowing how to figure angles correctly can result in better-looking projects which are faster to build and easier to reproduce accurately. Being able to handle this aspect of woodworking effectively can improve a worker’s overall craftsmanship and help speed up construction time while still achieving a professional quality finish.

Understanding the Terminology of Angles in Woodworking

When it comes to woodworking, angles are vital tools. The most common angle in woodworking is a 90-degree or right angle. It is used to create joints and corner pieces, as well as make doors or cabinets flush.

Other common angles include acute angles, which measure less than 90 degrees and obtuse angles, which measure more than 90 degrees. A straight angle measures 180 degrees and is equal to two right angles. Another important measurement for woodworking is the miter cut. This is when you cut two pieces of wood at the same angle so that their joints meet perfectly when butted together. It can refer to a square corner joint (two 45-degree cuts) or an angled one (two 22.5 -degree cuts). Finally, when creating a butt joint, you’ll need to ensure each piece uses miters with complimentary angles (one 22.5-degree cut and one 67.5-degrees cut).

Elevations are also used in woodworking for indicating how high a structure should be built from the ground level up to its roof peak. Most elevations use three lines: plumb line, level line and roof line that are typically drawn on plans using 30-, 45-, and 60-degree angles respectively. This will help you achieve an accurate height while keeping the roof at an appropriate slope for water runoff and ventilation needs depending on the climate where it’s being built. Lastly, following best practices in measuring angles and heights is vital for accurate results in any given project!

Illustrating Different Types of Angles commonly Used

A basic understanding of angles is essential to woodworking. Different types of wood joinery and decorative elements require different types of angles, each varying in degree. The most basic common angle is a right angle. This is where two lines are at an angle of 90 degrees relative to each other, with the point running parallel along a single plane. Acute angles measure less than 90 degrees, while obtuse angles measure more than 90 degrees. There are also complementary angles (two angles which combined complete 180 degrees), vertical angles (the mirror-image angle across from another angle) and adjacent angles (two angles that share the same vertex). Finally, curved or jogged angles go against straight ones, taking on a curved shape instead.

Utilizing Tools for Measuring and Calculating Angles

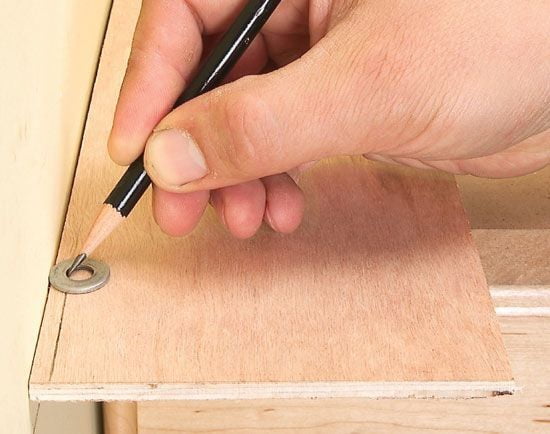

When woodworking, it is important to be able to accurately measure and calculate angles. To do this, woodworkers need a variety of tools to help them figure out specific angle measurements. For example, a combination or sliding square can be used to measure the inside and outside angles of mitered corners; an angle gauge can also be handy for transferring angles from one piece of material to another; and a protractor can be helpful for measuring the degree of an incline or a curved surface. Additionally, it is important to have other tools that help with calculating angles such as – speed squares, adjustable jigs and squares, trigonometry charts, rulers, calculators and special templates. All these tools should help a woodworker measure and calculate angles to ensure accuracy in their work.

Making It Easier

Using a protractor to figure angles in woodworking can seem daunting. But following some basic step-by-step instructions makes it simple and easy, no matter what angle you need.

First thing to do is get the right tool. A basic protractor is inexpensive and can be purchased at most hardware stores and home improvement centers. Once you’ve got the tool you’re ready to start measuring and marking angles for your next project.

Begin by placing the protractor on either side of the object whose angle you want to measure or create. Line up one side of the base of the protractor with the corner of your object, so that it forms a 90-degree angle. Then adjust the ruler arm or sliding head on top until it lines up with an edge or other point on your object so that you have identified two lines known as rays which create an angle between them.

Next use the scalene, or longest section around the outside edge, to find out how many degrees (or parts) the angle measures in total. Count out how many numbers on the scale equal to that part of your calculated angle, then note them down for use later.

Once your measurement has been taken, draw a line from where both rays meet at an acute (less than 90 degrees) or obtuse (greater than 90 degrees) angle as per your measurement from earlier in order to replicate it onto another piece of wood or material for joining together.

By following these simple steps anyone can now draw angles with ease!

Knowing What to Look Out For

Woodworking involves cutting and sculpting pieces of wood into a desired shape. The key to have success in this type of art is accuracy and precision. Figuring angles in woodworking can be challenging as there are a lot of measurements to consider and remember. However, there are some tips that can help you cut accurately and precisely.

First, make sure that you measure the entire piece of wood that you’re working with before cutting any of the individual pieces. This will give you an accurate sense of how thick the board is and how far the cuts need to go. Second, pay attention to the grain of the wood; this will help guide your cuts, especially when cutting angled surfaces or curves in the wood. Third, use a protractor to take precise angle measurements if needed. Lastly, always double-check your measurements before committing them to the saw blade or tools being used for your project.

Using these four steps can help ensure that all angles for your projects come out accurate and precise when finished. Additionally, taking time to practice figures using scrap pieces of wood will help build your skills and may even bring some unexpected results from experimentation!

Managing Sensitivity

When it comes to woodworking, accurate measurements of angles are vitally important. Every piece must fit together perfectly for the item to look good and function well; thus, any mistake on the angle will result in failure of the project. Due to this, there is a great deal of sensitivity surrounding angle measurements in woodworking projects. In order to minimize the risk of measurement errors, careful consideration must be taken during every angle.

Before even attempting any woodworking project, it is important to become familiar with basic tools such as rulers, protractors and squares. It can also be helpful to practice using these tools on scrap pieces of wood so that you feel comfortable and confident calculating angles accurately when working on the real thing. Additionally, by utilizing devices like a combination square or an adjustable bevel gauge which allow for fine adjustments on an angle can further improve accuracy when measuring angles. Finally, if your project requires extremely precise results for intricate details or special details in shapes that cannot be achieved through manual measuring tools (such as curves), consider investing in a digital measuring device with repeatable results so that you can insert predetermined values as needed for those more delicate areas. By following these simple steps and utilizing high-quality equipment you should be able to achieve accurate results with very little room for error in your woodworking projects.

Knowing the Basics

When it comes to making accurate cuts when woodworking, it is essential to have an understanding of angles. Understanding how to calculate and measure angles accurately will help ensure your woodworking project is professional looking and that you get the desired results. However, with so many things to consider while cutting wood, there are some mistakes people commonly make when figuring angles in woodworking.

The first common mistake people make is attempting to measure angles without a tool specifically designed for it. Every angle requires a different kind of measurement tool depending on the type of projection or miter cut, so having the right tool is crucial for accurate measurements.

Another mistake is measuring inside the box. Simple geometry states that measuring inside the box can result in inaccurate measurements, as walls can often be uneven and not symmetrical. Instead, try to use outside measurements wherever possible when calculating angles in woodworking projects.

Attempting complex angular calculations without using proper techniques or tools is another mistake which should be avoided whenever possible. While some calculations may seem simple, they can quickly turn into complicated math problems if not approached carefully and correctly. A good way to avoid this type of slip-up is by using specific digital tools meant for angular calculations and plotting out charts ahead of time to plan where cuts need to be made before starting a project.

Finally, miscalculating when dealing with complimentary angles should also be avoided at all costs. Complimentary angles are two angles whose sum adds up to ninety degrees; this means that if one angle measures ten degrees (10º), the other must measure eighty degrees (80º). Miscalculating this type of measurement can quickly derail any project, causing more frustration than necessary. Taking advantage of chart calculators online can help easily avoid these kind of errors from happening in the first place by doing everything from subtraction and addition needed for these types of measurements in no time at all!

Conclusion

When it comes to completing a successful woodworking project, accuracy is essential. Using the correct angle when cutting and joining pieces of wood can make all the difference in terms of durability and aesthetic appeal. By following best practices for measuring angles and using suitable tools for cutting them, you’ll be able to construct projects that look great and stand up to use for years to come. As a woodworker, taking the time to ensure your cuts are precise will pay dividends in the form of a more professional quality finished product. Knowing how to figure angles correctly is an essential part of any successful woodworking project.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.